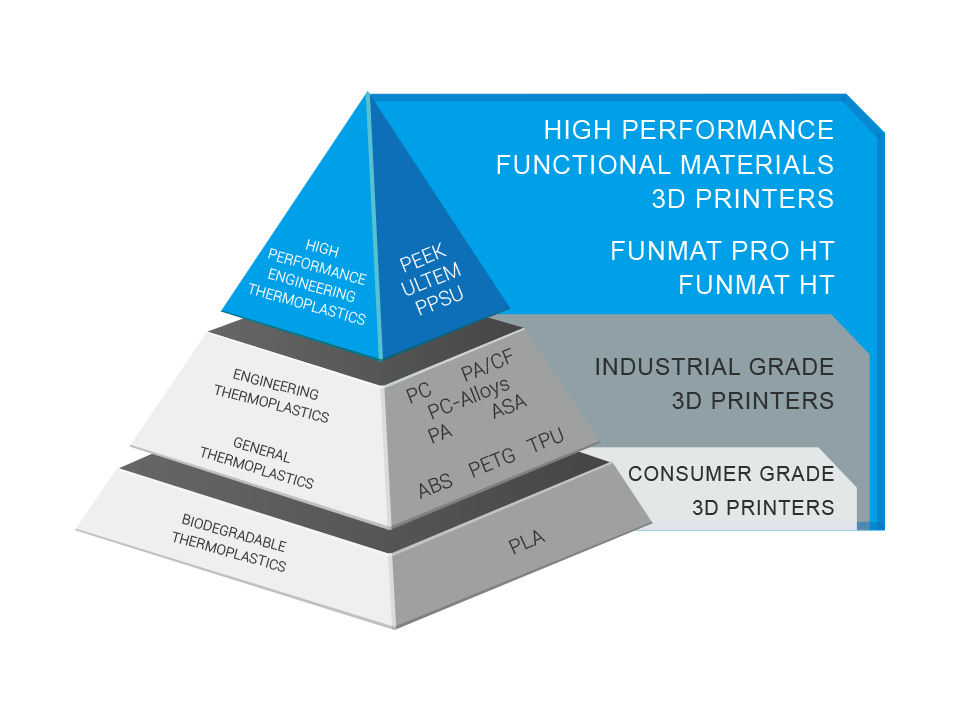

3D Printing of High Performance Functional Materials on INTAMSYS FUNMAT PRO HT & FUNMAT HT

FUNMAT HT and FUNMAT PRO HT are the latest High Performance Series 3D printers introduced by INTAMSYS. Equipped with 450°C high temperature nozzle, 160°C heated build plate, heated constant temperature chamber, power failure recovery, modular motion structure and advanced features, these two 3D printers are engineered to 3D print PEEK, ULTEM, PPSU and a broad range of thermoplastics.

PEEK, ULTEM and PPSU are high performance engineering thermoplastics ideal for demanding automotive, aerospace, industrial, oil and gas, dental, research and medical applications.

- PEEK (Polyetheretherketone) is considered as one of the world’s highest performing engineering thermoplastics. This semi-crystalline thermoplastic offers exceptional chemical resistances and retains excellent mechanical properties at high temperatures.

- Attributes of high thermal properties, inherent flame resistance and excellent dimensional stability are found in ULTEM / PEI (Polyetherimide). ULTEM has good resistance to a broad range of chemicals, such as automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions.

- PPSU (Polyphenylsulfone) is a high performance amorphous thermoplastic capable of resisting common acids and bases over a wide range of temperatures. This polymer offers superior thermal, chemical and hydrolysis resistances.

With INTAMSYS’ most advanced 3D printers – FUNMAT PRO HT and FUNMAT HT, users can also perform full size 3D printing in PC (Polycarbonate), NYLON-Carbon Fiber, PC/ABS and many more materials, all on ONE machine.

Contact: Chun Pin Lim cp.lim@intamsys.com