September 9, 2021, Shanghai, China – INTAMSYS, an industrial 3D printer solutions provider, announces its partnership with BASF Forward AM to expand industrial-grade 3D printing applications. Forward AM and INTAMSYS leverage both capabilities to meet the needs of industrial 3D printing customers.

"INTAMSYS is one of the leading solutions providers for Additive Manufacturing with customers across different industries, and we are happy to partner with them and leverage each other’s capabilities on machines and high-performance materials."

BASF Forward AM has developed a series of high-performance engineering materials for FFF technology and its new products Ultrafuse® PC/ABS FR and Ultrafuse® PPSU performed very well on INTAMSYS high-temperature printer PRO 610 HT and will be available soon on INTAMSYS’ CAEP program (this program provides the best printing profiles for FUNMAT printers, with diverse materials from top filament manufacturers, to meet customer demand for different applications).

Ultrafuse® PC/ABS FR has a mix of the excellent mechanical properties of PC and the comparably low printing temperature of ABS. Parts printed with this material feature great tensile and impact strength, higher thermal resistance than ABS, and can fulfill the requirements of the UL94 V-0 standard.

Ultrafuse® PPSU has outstanding thermal stability, good chemical resistance, and high strength. It has good layer adhesion that leads to balanced flexural strength properties between z- and x-direction and can be used for functional applications which require a high mechanical strength as well as a high heat distortion temperature – properties, where existing 3D printing materials often show limitations.

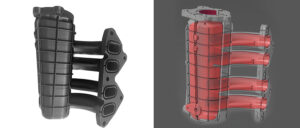

Photos: Ultrafuse® PC/ABS FR and Ultrafuse® PPSU printed parts

"INTAMSYS has always been committed in providing industrial 3D printers with open-source material systems to enable customers to choose the most suitable material solutions for their needs. We work with the world’s leading material providers to verify and optimize the printing process, empower customers’ applications, and greatly enhance customers’ 3D printing experience. BASF is the world’s top chemical company, and its PC/ABS FR and PPSU materials have excellent properties and perfectly match our FUNMAT series of 3D printers. Partnering with BASF Forward AM to promote industrial-grade FFF 3D printing solutions will create value for our industrial customers."

INTAMSYS has carried out a series of tests using the latest system, the FUNMAT PRO 610 HT. This printer is equipped with all-metal dual nozzles with temperatures that can go up to 500°C and is specifically designed to print high-performance and high-temperature materials. And BASF Ultrafuse® PPSU has been put successfully to the test.

By enhancing the chamber temperature to a constant 300°C, the PRO 610 HT was able to solve the issues of part warpage while offering a consistent, quality part every time. It can print different types of high-performance materials, such as PEI, PEEK, PEKK, PPSU, etc. In all the tests carried out, it has been found that when printing BASF Ultrafuse® PPSU at a high temperature of 220℃, the printed parts can avoid shrinkage and warpage.

BASF 3D Printing Solutions GmbH

Headquartered in Heidelberg, Germany, is a 100% subsidiary of BASF New Business GmbH. It focuses on establishing and expanding the business under the Forward AM brand with advanced materials, system solutions, components, and services in the field of 3D printing.

BASF 3D Printing Solutions is organized into startup-like structures to serve customers in the dynamic 3D printing market. It cooperates closely with the global research platforms and application technologies of various departments at BASF and with research institutes, universities, startups, and industrial partners. Potential customers are primarily companies that intend to use 3D printing for industrial manufacturing. Typical industries include automotive, aerospace, and consumer goods. For further information please visit: www.forward-am.com.

INTAMSYS Technology

INTAMSYS is a world-leading high-tech company providing 3D printing and industrial direct additive manufacturing solutions for high-performance materials. It is co-founded by a team of engineers from world-class high-tech companies engaged in precision equipment development and high-performance materials research for many years.

Focusing on aerospace, aviation, automotive, electronic manufacturing, consumer goods, healthcare, scientific research, and other industries, the company provides comprehensive additive manufacturing solutions from functional test prototyping, tooling, and fixture manufacturing to direct mass production of final products, covering equipment, software, high-performance materials, and printing services.

One Comment