Over the course of the last few years, high-performance polymers have seen exponential growth within the additive manufacturing space. Materials like PEI, PEEK, PEKK, and PPSU have opened the door for end-use applications that in the early days, one could only wish were possible.

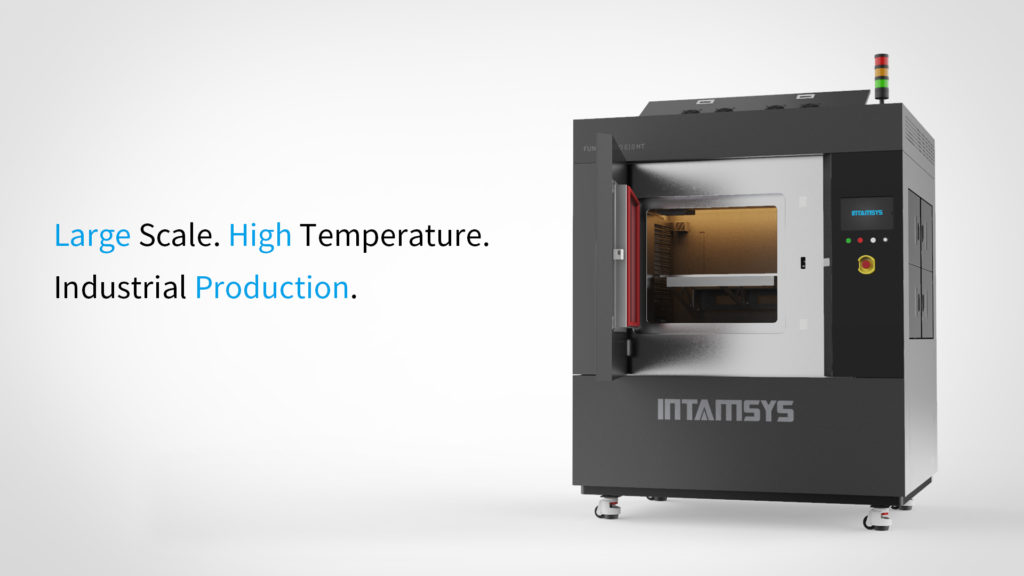

With that dream now a reality, INTAMSYS has paved a way with their breakthrough FUNMAT PRO 610 HT. Unlocking the potential of industrial-grade, high-quality 3D printing, equipped to effectively handle the tough requirements needed for these high-performance thermoplastics.

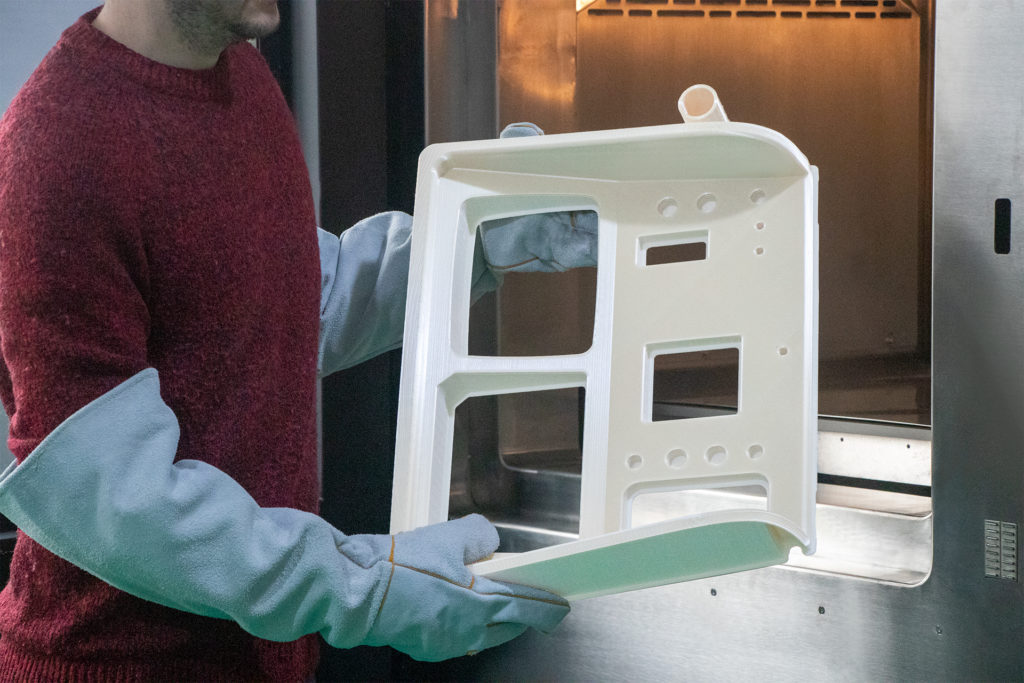

The FUNMAT PRO 610 HT comes with a print volume of up to 610x508x508mm (24x20x20in), allowing users to print large parts or multiple smaller parts for low volume production runs. Since large-scale printing requires significant motor speed and positioning accuracy, the FUNMAT PRO 610 HT comes equipped with a Servo control system. This enhancement improves the efficiency, while maintaining high axial rigidity and high transmitting precision.

Advanced thermal design

Equipped with a special nozzle, which can bear up to 500 °C, the FUNMAT PRO 610 HT can support almost every high-performance thermoplastic material available on the market. By enhancing the chamber temperature to a constant 300°C, the 610 HT was able to solve the issues of part warpage while offering a consistent, quality part every time.

3D Printing gets Bigger, Faster, and Stronger

Current 3D printing technology has enabled customers to print end-use parts that are both lighter and stronger, while creating tools that have pushed the boundaries of industrial applications. Aerospace and automotive in particular, have been huge benefactors of 3D printing as well as early adopters of the end-use capabilities that 3D printing now provides. Currently, ULTEM 9085 is utilized within aerospace for tough, lightweight parts that otherwise would have needed to be machined.

INTAMSYS is dedicated to providing industrial-grade 3D printing solutions for industrial applications. The open material eco-system has been in the DNA of INTAMSYS since the beginning. Since high-performance materials normally require exceptionally low humidity, we have equipped the FUNMAT PRO 610 HT with an active drying system for the filament chamber, helping the material remain moisture-free, resulting in a high printing quality.

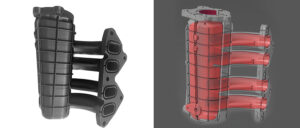

The dual-nozzle design (with up & down movements) supports the printing of complex structures, while the system also includes user-friendly features like automatic cleaning, filament jam detection, and auto-nozzle calibration. The modular designed nozzle system ensures a longer lifetime and is easy to be replaced or maintained during the life span of the system.

Health and Safety

As a world-leading supplier for industrial-grade FFF 3D printers, INTAMSYS always puts the operator’s health and safety on top of any other considerations. Optimized design safety locks and safety PLC meet the D safety level for the CE Machine Directive regulation.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]