Introducing the FLEX 510

JUNE 15 2020

Shanghai, China – June 15th 2020, the leading industrial 3D printer manufacturer INTAMSYS, a 3D printing machine for high performance material production-grade applications, releases it latest addition to its AM solutions portfolio, the FLEX 510, a high-speed 3D printer for flexible materials production.

Specially designed for the produce of sporting goods, medical rehabilitation equipment and tooling and fixtures, the newly announce FLEX 510 is INTAMSYS latest cutting-edge 3D printing solution.

The INTAMSYS FLEX 510 is another breakthrough 3D printing solution INTAMSYS Technology. The FLEX 510 solves several of key issues when it comes to printing flexible materials. Among those issues are the difficulty to print flexible materials at high speeds. The FLEX 510 has been provided with the SXBS™(Smart eXtruder Bay System) technology which enables a seamless design and manufacturing connection. Flexible materials such as TPU, combines the characteristics of plastic and rubber, and can produce elastic, highly durable, bendable or compressed parts, which is the best choice for sporting goods design, fashion design and medical rehabilitation equipment. “We believe that the introduction of the FLEX 510 will accelerate the innovation of these industry’s design and the manufacturing process and push more and more related industries towards customized smart manufacturing,” INTAMSYS Marketing Director Colin Fei said.

High-Speed Printing | Designed for Production

The FLEX 510 incorporates the HSFE™ (High Speed Flexible Material Extrusion) technology, a high-speed flexible material extrusion technology developed by INTAMSYS, which solves one of the industry biggest challenges, a slow process caused by flexible materials being too soft to feed through the system at a fast pace. The overall printing efficiency can be increased by more than 5 times. Thanks to an independent dual-nozzle configuration, you can achieve duplicate printing or mirror printing, at an ultra-fast pace, thus helping solve 3D print production efficiency constraints.

Break through design limitations | Higher design freedom

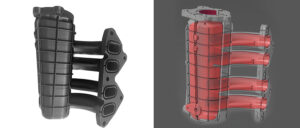

Existing material extrusion 3D printing equipment generally comes with a single nozzle, dual nozzles or mixed nozzles with multiple materials. The printed model can only be compatible with at most two materials and cannot meet the printing needs of multiple colors and multiple material models.

INTAMSYS’s SXBS™ technology enables you to manage up to four nozzles which can freely switch during the printing process, and enables you to print up to four different TPU materials or four different colors per print, thus enhancing the printing efficiency.

If designers can implement and iterate designs much faster, they can get products into the market faster. INTAMSYS’s unique technological innovation will bring designers unparalleled design freedom and flexibility. Now they can seamlessly bring design and manufacturing together, accelerating the progress of 3D printing to mass customized manufacturing.

Smart design | Reduced manual intervention

The FLEX 510 uses AAL™ (Active Automatic Leveling technology) saving customers precious time as they do not need to manually adjust the platform parameters. The feature reduces the need for print process and machine operation knowledge at the users’ level and improves the level of first time right printed product without compromising the quality and speed of the printed product.

About INTAMSYS

INTAMSYS is a fast-growing industrial-grade 3D printer manufacturer. INTAMSYS serves the world’s leading customers in the fields such as aerospace, automotive, electronics manufacturing, medical, education and scientific research. With innovative additive manufacturing solutions, it promotes the development of industry technology and expands the application fields of 3D printing. From functional testing to end-use products, from personalized customization to large-scale manufacturing, INTAMSYS continues to add new value to the industry through technological innovation and thus broadens the boundaries of the industry.

Contact: info@intamsys.com

One Comment