INTAMSYS – 2018 Jigs & Fixtures Competition Results !

NOV 15, 2018

INTAMSYS is delighted to announce the results of the 2018 Jigs & Fixtures Competition.

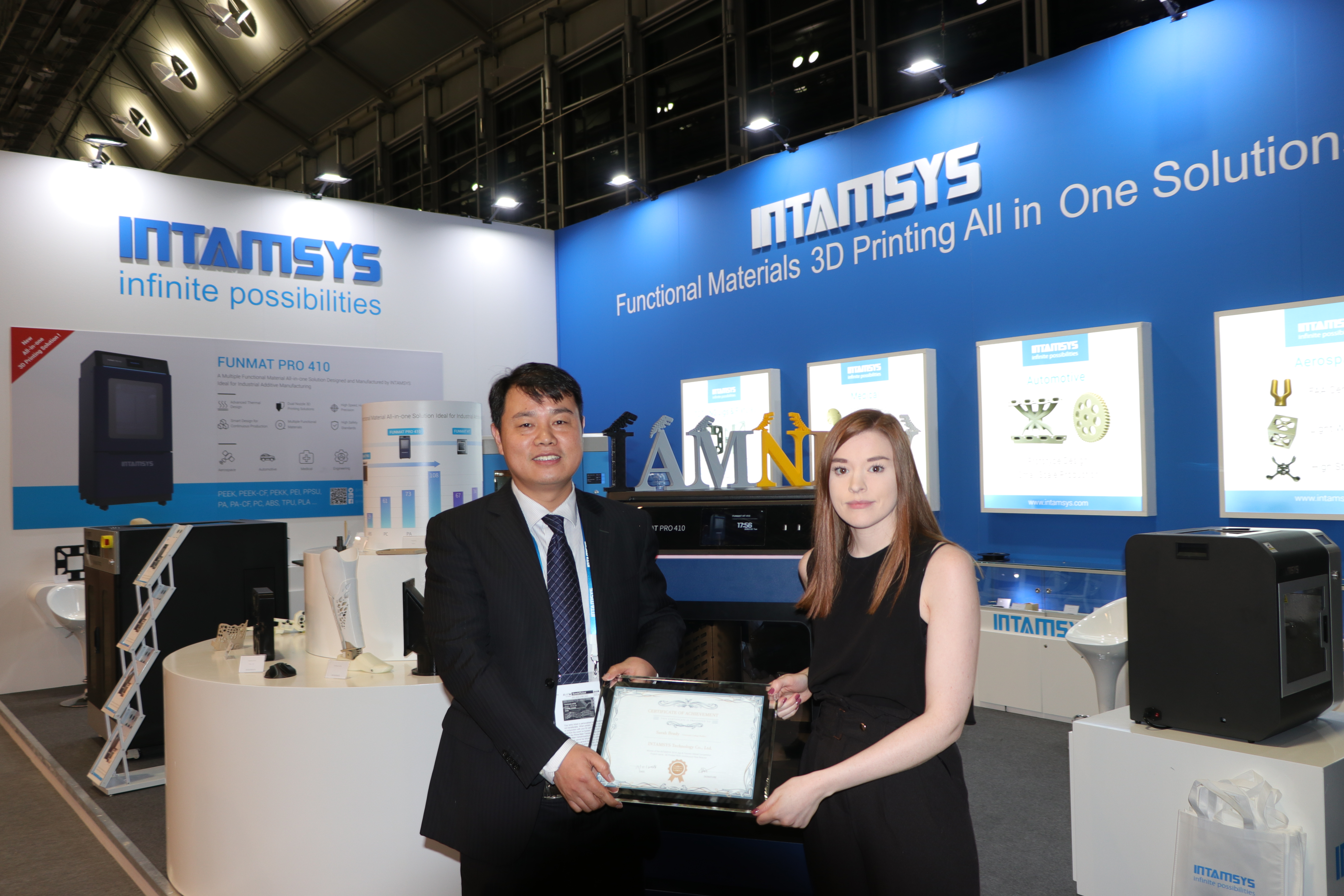

CONGRATULATIONS to Sarah Brady and all the I-Form researchers who won the top prize ! We were truly impressed by the quality of the project your team submitted.

CONGRATULATIONS as well to Clayton Young from Muncie Power and to 李云舟 from Hasco Vision, who won respectively the 2nd and 3rd prizes !

CONGRATULATIONS to everyone who participated in the competition, the overall quality of the different projects was very impressive !

You will find below the detailed project of the winning team – comprising UCD-based researchers in I-Form, the SFI Research Centre for Advanced Manufacturing.

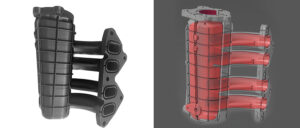

Project Name : ‘’3D Printed PEEK Continuous Flow Reactor’’

The winning entry was a cross-disciplinary collaboration from an engineering team based at University College Dublin: the reactor was 3D printed by I-Form’s Dr Sarah Brady, under the supervision of I-Form centre director Prof. Denis Dowling. The reactor was designed by Dr Matthew Harding and Dr Steven Ferguson in UCD Chemical and Bioprocess Engineering, who are evaluating it for use in the intensified chemical synthesis of drugs. I-Form is an SFI Research Centre whose mission is to shape the future of manufacturing through high-impact research into the application of digital technologies to materials processing.

“I’m delighted to see the creativity and expertise of Irish researchers working in advanced manufacturing being recognised in this international competition,” said Prof. Dowling, I-Form’s Centre Director. “Additive manufacturing (3D printing) opens up a world of possibilities for industrial processes. At I-Form we work closely with industry to advance the low-cost, low-risk design of new products and the manufacture of high-value components with enhanced material performance, alongside the reduction of processing times and enhancing process reliability.”

The INTAMSYS award was for the design and print of a disposable 3D printed reactor for carrying out chemical reactions: As the materials move through the reactor, they mix and react to form the pharmaceutical intermediates or product. The part is known as a continuous flow reactor. This type of reactor is now becoming common within the pharmaceutical manufacturing sector, as they allow product to be produced continually, under more aggressive conditions, with better control over heating, cooling and improved mixing, enabling much faster reactions to be conducted. This can enable dramatic reduction in facility size and cost, with equivalent production rates.

One advantage of using 3D printing for the fabrication of flow reactors is design flexibility. In this example, the mixing chamber inside the reactor can be designed specifically to match the characteristics of a given reaction mixture, allowing the optimum reactor to be printed on-demand, at a fraction of the cost of traditional fabrication techniques.

The continuous flow reactor was printed using an INTAMSYS FUNMAT HT using PEEK material.

For further information about our printers, please contact info@intamsys.com

For further information about the winning project, please contact:

Sylvia Leatham sylvia.leatham@i-form.ie I-Form Advanced Manufacturing Research Centre +353 (01) 716 2956 or +353 (0)87 6288355

Contact: info@intamsys.com