INTAMSYS Officially Enters into Japan by Partnering with Fusion Technology and Canon

JUNE 20, 2018

SHANGHAI & TOKYO– INTAMSYS, an industry leader in PEEK and high-performance functional materials 3D printing solutions, announced today that the company has established a partnership with Fusion Technology Co. Ltd. to enter into the Japanese industrial additive manufacturing market.

Fusion Technology is an acclaimed Japanese firm in designs and 3D printing expertise for architecture, manufacturing, medical, anime, education and other industries in Japan.

The partnership also involves Canon Marketing Japan Inc, a reselling partner of Fusion Technology in Japan, to jointly promote and market INTAMSYS 3D printers and printing solutions to industrial companies in Japan.

Mr. Inoue, CEO of Fusion Technology, said, “More Japanese industrial manufacturers are increasingly embracing industrial additive manufacturing solutions for business-critical applications due to strong quality, high consistency and cost effectiveness. INTAMSYS has presented a strong proven track record of delivering cutting-edge high performance material 3D printing solution to industrial end-users globally. Meanwhile, Fusion technology has built up a broad industrial customer base locally through decades of successful reselling experience, evidenced by our direct partnership with Canon. We believe this cooperation will complement each other very well in exploring more markets and possibilities in Japan.

From June 20th to 22nd, together with Fusion Technology and Canon, INTAMSYS will exhibit at the DMS Tokyo in Japan. And, both the FUNMAT PRO HT and FUNMAT HT will be showcased for the first time in the country.

“Globally, Japanese firms have earned the reputation of having very high requirements on quality and reliability for machinery. INTAMSYS is delighted to be recognized by Fusion Technology and Canon through this strong partnership and we look forward to serving the Japanese end users with machines and 3D printing solutions that come with the highest quality and state-of-the-art engineering capability.” said Charles Han, CEO of INTAMSYS.

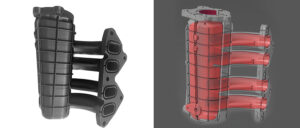

INTAMSYS specializes in producing reliable industrial-grade 3D printers with excellent multiple industrial materials capability. The company’s FUNMAT HT and FUNMAT PRO HT 3D printers are capable of 3D printing more than 20 functional materials due to their state-of-the-art thermal technologies on the active heated chamber, high temperature nozzle and heated build plate. The six high-performance materials supported are PEEK, PEKK, ULTEMTM 9085, ULTEMTM 1010, PPSU and PSU.

The industry-leading capability of the FUNMAT PRO and FUNMAT PRO HT is the unique full-size (450 x 450 x 600mm) 3d printing solutions for the 3 most widely used engineering-grade thermoplastics at industrial settings – polycarbonate (PC), ABS and nylon.

Additionally, the open materials system of INTAMSYS is highly welcomed by its industrial customers who see it as a strategic and highly cost-effective long-term investment for their companies.

Globally, INTAMSYS works closely with industrial customers and partners from the aerospace, automotive, medical, engineering, oil & gas, electronics, education and research industries to further advance additive manufacturing applications in tools, jigs and fixtures, concept modeling, visualization aiding, functional prototyping and end-use parts manufacturing.

Contact: Chun Pin Lim cp.lim@intamsys.com